Lockheed Martin workers put the ‘backbone’ into satellites for military, broadcasting uses

May 29, 2015

The satellite propulsion systems manufactured by Lockheed Martin at Stennis Space Center are critical to U.S. and foreign military communications and for high-definition television broadcasting to international audiences.

Ninety percent of Lockheed Martin's satellites have come through the Mississippi Space and Technology Center since it opened in 2002. Most of the 55 propulsion systems completed at the Hancock County facility have been for military communications and HDTV broadcasters.

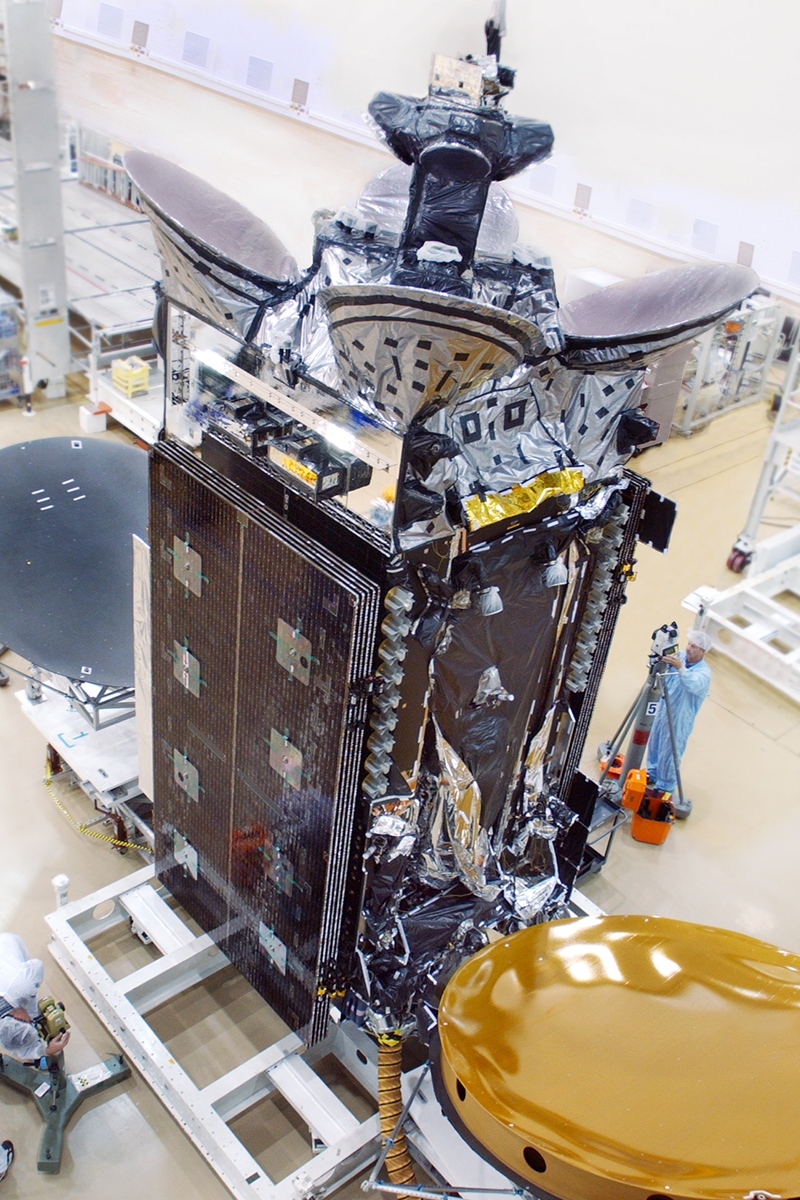

As part of the satellite propulsion system build process, Lockheed Martin's workforce of approximately 165 employees installs the rocket engines, fuel tanks, extensive tubing and thermal protection into the satellites which are then sent to other Lockheed Martin facilities for final assembly before launch.

Dave Hartley, director of the Propulsion Manufacturing Center at the Stennis site, said the propulsion system performs as the satellite's backbone. Its rocket engines boost the satellite from low earth orbit to geosynchronous orbit and nudge the satellite into its final destination position to perform the tasks it is designed for.

Among the propulsion systems completed at Stennis are the AMC 18, a geostationary communications satellite launched in 2006 that distributes high definition television signals to all 50 states. Another Lockheed Martin Stennis satellite is GOES-R, which contains a new generation of geostationary Earth-observing systems that provides accurate real-time weather forecasts and early warning. The GPS III next-generation of Global Positioning System satellites assembled at Stennis provide positioning, navigation and timing services to military and civilian users.

Four propulsion systems are currently in production at Stennis: a NASA/NOAA GOES next generation weather satellite, two Military Advanced Extremely High Frequency (AEHF) satellites and an Australian communications satellite.